La ligne de production d’épis de maïs doux sous vide est un système industriel complet conçu pour automatiser le traitement et le scellage sous vide des épis de maïs doux. Ce type de ligne de production est largement utilisé dans l’industrie alimentaire pour produire des produits de maïs doux prêts à cuire ou prêts à consommer avec une durée de conservation prolongée. Nous pouvons obtenir des épis de maïs doux sous vide qui peuvent durer 1 an sans pourrir ni pourrir.

Le maïs doux est une variante génétique naturelle du maïs de grande culture qui permet aux grains de stocker plus de sucre que le maïs de grande culture. Environ 70 % d’entre eux ont été produits pour le marché du frais et 30 % pour le marché de la transformation (maïs surgelé ou maïs en conserve). Le maïs doux frais a la caractéristique génétique d’inhiber la conversion du sucre en amidon. Par rapport au maïs ordinaire, le maïs doux présente des différences évidentes dans la teneur en amidon, sucre, protéines, matières grasses et vitamines. La teneur en protéines des grains de maïs doux frais est supérieure à 13 %, la teneur en sucre est supérieure à 10 % et la teneur en matières grasses brutes est d’environ 9,9 %. Chaque 100 g de maïs doux contient 0,7 mg de vitamine C, 0,22 mg de niacine et de vitamine B2 et 1,70 mg de riboflavine et de vitamine B2. De plus, le maïs doux contient également une variété de substances aromatiques volatiles, de minéraux, de fibres alimentaires, d’oryzanol, de stérols et d’autres ingrédients.

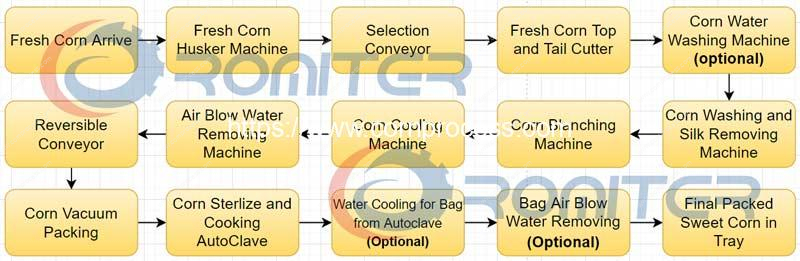

L’emballage sous vide est l’une des technologies courantes pour le traitement et la conservation des épis de maïs doux. Il est combiné aux processus de récolte, de nettoyage, de découpe, de précuisson, de stérilisation, de congélation et de stockage final. Chaque étape de traitement joue un rôle essentiel dans la qualité de stockage finale et la durée de conservation du maïs doux. L’épi de maïs doux emballé sous vide est facile à vendre directement sur le marché.

La ligne de production automatique d’épis de maïs doux emballés sous vide comprend principalement une décortiqueuse de maïs doux, un convoyeur de sélection de maïs doux, un coupe-queue et de haut d’épis de maïs doux, une machine à laver les épis de maïs doux frais, une machine de nettoyage de soie d’épis de maïs doux frais, une machine de blanchiment d’épis de maïs doux frais, une machine de refroidissement d’épis de maïs doux, une machine d’élimination par soufflage d’eau de surface d’épis de maïs doux, une machine d’emballage sous vide d’épis de maïs doux, une machine de cuisson et de stérilisation d’épis de maïs doux, une machine à laver les sacs d’épis de maïs doux emballés sous vide et une machine d’élimination par soufflage d’eau de surface d’épis de maïs doux emballés sous vide.

1. Air Blow Type Fresh Sweet Corn Husker Machine

Stainless Steel Air Blow Type Sweet Corn Dehusking Machine is used to remove the husks or outer layers from sweet corn cobs using an air-blowing mechanism. This type of machine is commonly used in commercial or industrial settings where large quantities of sweet corn need to be processed efficiently. fresh Sweet corn cobs are fed into the machine’s inlet hopper or conveyor system and worker need to put the sweet corn in the right position. The sweet corn husk removing machine uses a combination of air jets and mechanical elements to remove the husks from the corn cobs. The air blowing mechanism directs high-speed streams of air onto the cobs, which helps loosen and blow away the outer husks. As the husks are blown away, the clean corn cobs are separated and collected for further processing or packaging.

Air Blow Type Sweet Corn Dehusker Machine can remove the sweet corn husk without any damage.

Working Video of Air Blow Fresh Sweet Corn Husker Machine

2. Sweet Corn Cob Top and Tail Cutter Machine

Automatic Fresh Sweet Corn Top and Tail Cutter Machine is designed to automatically to cut the top and tail of fresh sweet corn. Sweet corn top and tail cutting machine cut the corn cob by using rotating blades. The workers put the fresh sweet corn in the chain feeding tray and the rotary cutting blade will cut one side first, Then following worker will adjust the sweet corn position to cut another side on the right position (We have one laser pen mark the cutting position to help worker move corn in the right position). so sweet corn top and tail are both cut. Corn Top and End Cutting Machines can be customized in a single lane or double lane depending on capacity needs. Corn top and tail cutting machines can help to reduce the amount of manual labor required in corn processing and improve the efficiency of the overall processing operation. They also help to ensure that the corn is cut uniformly, which can improve the quality and consistency of the final product. This is an essential step in the corn processing line, particularly when preparing sweet corn for further processing, packaging, or cooking. This machine is commonly used in commercial food processing facilities to increase efficiency and productivity.

Working Video of Sweet Corn Cobe Double Side Cutting Machine

3. Fresh Sweet Corn Cob Washing Machine

Automatic Cutted Corn Cob Coarse Washing Machine is used to wash the cutted sweet corn. It also has a pneumatic conveyor bucket lift device, which allows workers to clean the machine very easily. After sweet corn cut, many impurity will go to this washing machine, the water will become very dirty after some time working. Our special design lift available water washing machine can make this step easy to clean. It is widely used in Vacuum Packed Sweet Corn Production Line.

4. Fresh Sweet Corn Cob Silk Washing Cleaning Machine

Automatic Corn Silk Washing Removing Machine(Automatic Corn Silk High Pressure Water Washing Removing Machine) is used to remove the corn silk from corn cobs. Corn Silk Cleaning Removing Machine adopts high-pressure water spray to remove the dirt and corn silk on the corn cob which can avoid damage during manual washing cleaning. The rolling rod feeding conveyor will make the corn rotary on during high-pressure water spray, so all sides of sweet corn can be cleaned. Corn cobs are fed into the machine by a conveyor belt. High-pressure water nozzles are strategically positioned to direct powerful streams of water onto the corn cobs. The water along with the removed silk and debris is directed through a drainage system. Cleaned corn cobs are then conveyed out of the machine for further processing or packaging. Corn Silk High Pressure Water Spray Washing Removing Machine is typically used in commercial food processing environments where large quantities of corn need to be cleaned quickly and effectively. Nowadays, it is widely used in vacuum-packed sweet corn processing factory.

Working Video of High Pressure Water Spray Sweet Corn Washing Cleaning Machine

5. Fresh Sweet Corn Cob Blanching Machine

Automatic Sweet Corn Cob Blanching Machine is used to blanch sweet corn cob to keep the color and nutrition. After sweet corn cutting, sweet corn is conveyed into the blanching machine. Blanching is carried out in an immersion-type blanching machine with water of 85 -95oC, the corns undergo the blanching process for 10-12 mins. The water in the blancher is heated using direct steam injection, which is absorbed completely into the water. The recirculation system requires very little steam to reheat the water.

Blanching is one of the stages of corn kernel technological production processes for consumer purposes. The blanching process significantly affects the quality of the corns. The main purpose of blanching is the inactivation of the tissue enzymes responsible for spoiling the material as well as undesirable changes in its color, taste, and texture.

Working Video of Sweet Corn Blanching Machine

6. Fresh Sweet Corn Cob Cooling Machine

After blanching, the ears of corn must be cooled in time, otherwise, the corn kernels will lose water and wrinkle due to high temperature, which will affect the appearance and quality of corn. On the contrary, if the temperature of the corn ear is too high, the moisture will evaporate during the vacuum packaging and produce steam, which will adversely affect the quality of the vacuum packaging.

Automatic Sweet Corn Air Bubble Washing Cooling Machine is used to wash sweet corn and cool the hot water-blanched sweet corn. This system uses air bubbles and water to clean the sweet corn. The bubbles help remove dirt, debris, and other contaminants from the corn kernels more effectively than just a water spray alone. The cold water will also cool the hot water-blanched sweet corn, which makes it is suitable for vacuum packing operation. Such a machine is designed to increase efficiency and ensure that the sweet corn is cleaned and cooled quickly and uniformly, which is essential for maintaining freshness and quality in large-scale food processing operations. It is widely used in the Sweet Corn Production Line.

7. Fresh Sweet Corn Cob Surface Water Air Blow Removing Machine

Rolling Bar Type Sweet Corn Air Blow Water Removing Machine is used to remove the sweet corn surface water by air blow. It is designed with rotary rolling rod conveyor, which makes the sweet corn rotary on the conveyor and all the sweet corn surface positions can be blown, so the water can be removed. The rolling rod conveyor also protects the sweet corn and avoids damage to sweet corn. This Air Blow Water Removing Machine is widely used in vacuum packed sweet corn production line.

Drying the corn cobs on an automatic drying machine before moving to the step of vacuum packaging.

8. Fresh Sweet Corn Cob Vacuum Packing Machine

Type A: Rolling Type Sweet Corn Cob Vacuum Packing Machine

Continuous Rolling Sweet Corn Vacuum Packaging Machine is used to pack sweet corn in vacuum condition, which can extend the shelf life. It employs advanced electrical control and an excellent braking device, the chain drives the conveyor belt to work, automatically swings the cover, and continuously outputs the finished products. The whole machine adopts waterproof and moisture-proof computer board control, the operating system is fully sealed, and the whole machine can be rinsed with water. This machine works with automatic lid swinging. Specifically, when the chain advances, it drives the conveyor belt to move forward, and the products can be placed on the conveyor belt to output products continuously.

Working Video of Rolling Type Sweet Corn Vacuum Packing Machine

Type B: Automatic Bag Feeding Corn Vacuum Packing Machine

Automatic Bag Feeding Corn Vacuum Packing Machine

Working Video of Automatic Bag Feeding Sweet Corn Vacuum Packing Machine

9. Vacuum Packed Sweet Corn Cob Cooking and Sterilizer Retort

Vacuum Packed Sweet Corn Cooking Sterlizer Autoclave Machine is used to cook and sterilize packed sweet corn cobs. After vacuum packaging, the packed cobs will be loaded into the stainless steel retort trays for retort sterilization process. A vacuum-packed sweet corn cooking sterilizer autoclave machine is used for processing and sterilizing vacuum-sealed corn products, typically in commercial or industrial settings. This machine ensures that sweet corn is properly cooked and sterilized to maintain quality and extend shelf life.

Water immersion sterilize retorts for sweet corns packed in vacuum pouches processing. Water immersion retorts are also the most commonly used in the producers’ plants.

It has larger capacity compared with other models of the same size vessel and allows the shorter come-up time. All sweet corns are deep in hot water during cooking phase that results in good flavor and appearance. Abundant feedback from our customers prove the water immersion retorts are the preferred in vacuum packed sweet corn industry.

Water immersion retorts can be designed in different configurations, dual tank design- top tank is hot water reservoir, bottom retort vessel, or several retort vessels sharing one hot water reservoir depending on the specific capacity.

Working Video of Vacuum Packed Sweet Corn Cooking Sterilizer Retort

10. Vacuum Packed Sweet Corn Cob Bag Washing Machine

Automatic Sweet Corn Air Bubble Washing Cooling Machine is used to wash sweet corn and cool the hot water-blanched sweet corn. This system uses air bubbles and water to clean the sweet corn. The bubbles help remove dirt, debris, and other contaminants from the corn kernels more effectively than just a water spray alone. The cold water will also cool the hot water-blanched sweet corn, which makes it is suitable for vacuum packing operation. Such a machine is designed to increase efficiency and ensure that the sweet corn is cleaned and cooled quickly and uniformly, which is essential for maintaining freshness and quality in large-scale food processing operations. It is widely used in the Sweet Corn Production Line.

Working Video of Sweet Corn Washing Cooling Machine

11. Vacuum Packed Sweet Corn Cob Bag Surface Water Air Blow Dryer Machine.

Turnover Mesh Belt Air Blow Water Removing Machine is used to remove the vacuum-packed sweet corn bag surface water. The turnover mesh belt conveyor makes the bag turnover during moving, so all the position of the bag can be blown by air and all bag surface water can be removed. It is widely used in Vacuum Packed Sweet Corn Production Line.

Working Video of Vacuum Packed Corn Air Blow Water Removing Machine

12. Vacuum Packed Corn Outer Bag Sealing Machine

Semi-Automatic Fresh Corn Bag Sealing Packing Machine is used for sealing plastic bag to pack fresh corn. This machine adopts electronic constant temperature mechanism and stepless speed adopts electronic constant temperature mechanism and stepless speed adjusts transmission mechanism, it can seal plastic film in various kinds of materials.

Working Video of Vacuum Packed Corn Outer Bag Packing Machine

FAQ for Vacuum Packed Sweet Corn Production Line

1. How to Plant Sweet Corn for Vacuum Packed Sweet Corn Line

We recommend planting sweet corn every 3-5days intervals on different fields, which makes sure you have enough time to harvest and process them to final vacuum-packed sweet corn.

Because the sweet corn harvest time is important for the taste if you harvest too late or earlier. we can not get bthe est taste of sweet corn. We also need to process the fresh corn within 24 hours after harvest. which can make sure to keep the best taste of fresh sweet corn

2. Whether need to add a Chemical Additive to the Vacuum Packed Sweet Corn

No. Generally. Vacuum-packed sweet corn does not need any chemical additives, just use machine cleaning, cooking, and sterilizer. Then the self-keep life will be 1 year.

3. What influence the taste of Vacuum Packed Sweet Corn Cob

Quality of Raw Sweet Corn. The basic factors that determine the edible and processing quality of sweet corn are the sugar content and water-soluble polysaccharide content of the kernels. Polysaccharide is a kind of multi-branched small molecular starch, which can be dissolved in water and has a waxy taste. It is one of the main factors that constitute the flavor of sweet corn. The tenderness of the peel is also one of the factors that affect the taste. Therefore, when corn is harvested, it is necessary to determine that the above three factors of sweet corn are in the best state according to observation and research.

Sweet Corn Blanching Time. On the one hand, blanching can inactivate the various enzymes present in the ears of sweet corn, so that the nutrients in the body will not be destroyed, and can effectively prevent the color change (the kernals might turn purple is not properly cooked) and prolong the storage period; on the other hand, it can kill the adhesion in the field. The microorganisms and insect eggs on the surface of the ears ensure the sanitation and edible safety of processed foods; it can also squeeze out the air in the tender corn tissue, increase the resistance to expansion pressure, and reduce the damage rate during sterilization; correspondingly reduce the oxidation of raw materials To a certain extent, it is conducive to preserving the color and nutrition of the product, and makes the ears of sweet corn have a sense of cooked food.

The formation of sweet corn flavor mainly depends on the degree of gelatinization of amylopectin in the endosperm of the pre-cooking stage. Only after all gelatinization, the sweet corn taste can be obtained, and the same flavor quality can be maintained after sterilization. However, if the gelatinization is not good, the amylopectin cannot be further gelatinized during sterilization. Make the product unsuitable for consumption. If the pre-cooking time is too long, the corn kernels will crack and the flavor will decrease. Therefore, we use its flavor, palatability, and grain cracking as indicators for comprehensive evaluation to determine the blanching time.

Sterilization. For most vacuum packages, through and in-time sterilization is the key to prolong the shelf life.

4. How to Order the Vacuum Packed Sweet Corn Cob Production Line

Please confirm the capacity of machine need (how many ear or pieces corn cob need to process per hour), Generally. during the harvesting season, the corn processing factory are working 24 hour, which make sure all the harvested corn can be processed in time to keep the best taste.

Confirm the max budget for the line. For the Packing machine, it have manual type or full automatic type, which cost total difference.

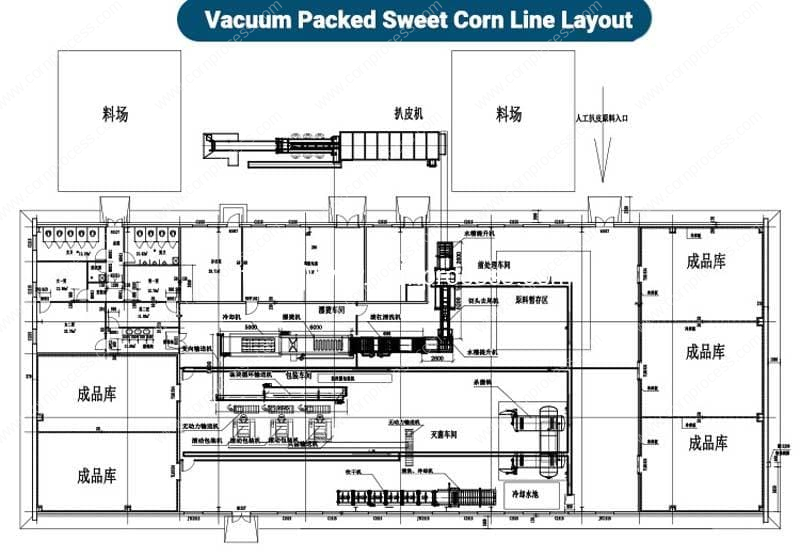

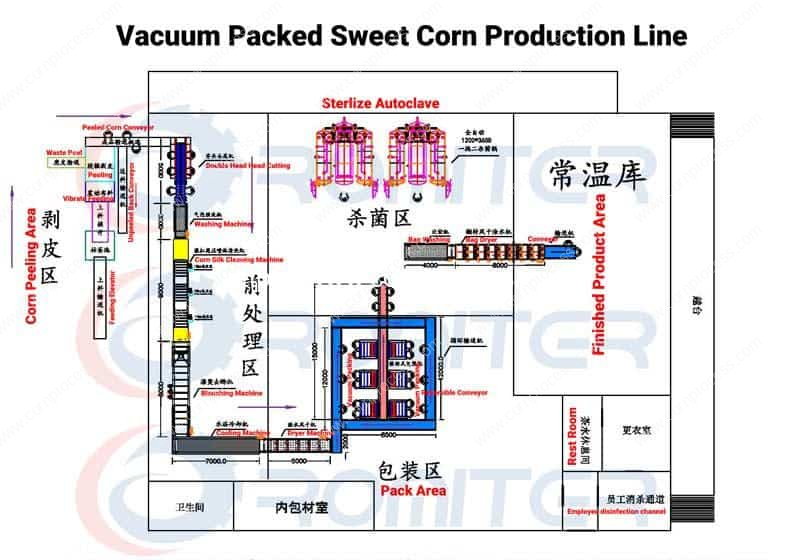

Vacuum Packed Sweet Corn Line Layout Drawing

Working Video of Vacuum Packed Sweet Corn Production Line

Company Profile

Romiter Machinery Co., Ltd. is a market-leading designer and manufacturer of corn processing machines. Romiter Machinery wins a wide reputation for high-quality machines with high efficiency, excellent reliability, easy maintenance, long lifespan and an excellent technical support team.

Now, Our factory can provide corn washing cleaning machines, corn dehusking machines, corn threader machines, corn cutting machines, popcorn making machines, kettle corn making machine, corn flakes making machines, steam flaked corn production line, corn packing machine, vacuum packed fresh corn production line, frozen sween corn kernel production line. corn flour milling machine, and corn grits milling machine

Romiter Group can provide customized machine for customers. Welcome to contact us for more information.